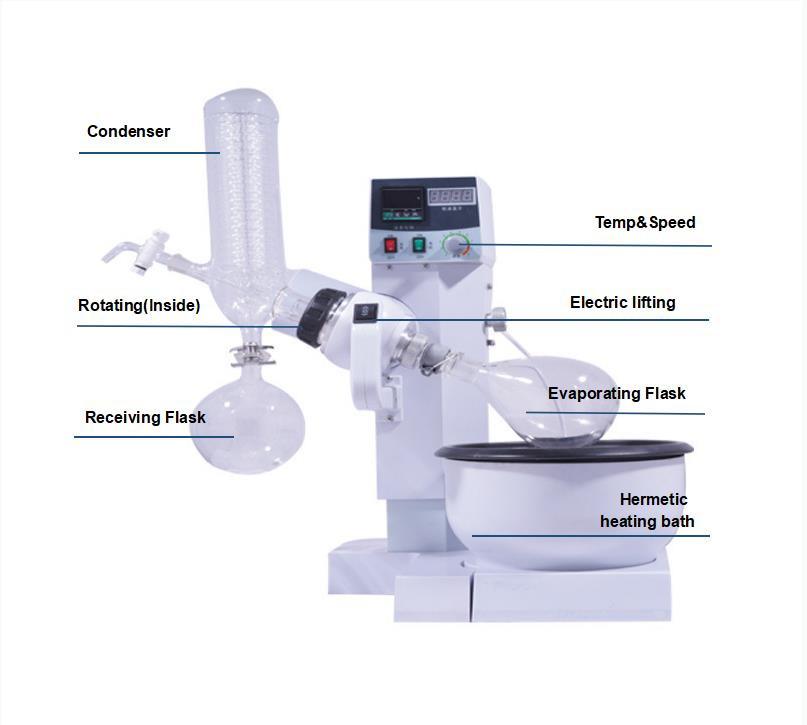

R-1020 2L,5L,10L,20L,50L,100L Rotavapor Rotary Evaporator

Detail

Rotary evaporators are mainly used for concentration, crystallization, drying, separation and solvent recovery in chemical and biopharmaceutical industries. The principle is: under vacuum conditions, constant temperature heating makes the rotary bottle rotate at a constant speed, and the material forms a large-area film on the bottle wall, which evaporates efficiently. The solvent vapor is cooled by a high-efficiency glass condenser and recovered in the collection bottle to improve the evaporation efficiency. It is especially selected for the concentration and purification of biological products that are easily decomposed and denatured at high temperature.

The rotary evaporator of our factory integrates the essence of similar products at home and abroad, and accumulates the company's successful practical experience. It has formed 2L, 5L, 10L, 20L, 50L, 100L series. The product design follows the principles of high efficiency, practicality and economy, and everything is for the sake of users.

YRE series rotary evaporator is a new type of desktop rotary evaporator developed by our factory. This product has a novel and beautiful appearance, the main body is made of aluminum alloy, the temperature is digitally displayed, the heating pot is made of Teflon composite material, and the fully enclosed heating mode prevents dry burning. , water and oil dual-use. The sealing part adopts foreign new technology, Teflon + fluorine rubber double sealing ring, to maintain a lasting high vacuum.

Technical Features

◆ Sealing structure and selected sealing materials,

◆ High evaporation efficiency, high recovery rate

◆ Modular serialized design, strong expansibility

◆ Easy to assemble and disassemble, easy to operate and easy to maintain

◆ Stainless steel (special plastic) chassis, columns, vertical shafts, aluminum alloy castings, beautiful appearance,

◆ The key seals, the electronic originals are imported

Products Parameter

|

Main engine |

Electric touch button |

Rapid automatic lift |

0-150 mm |

Cooler

|

Vertical. High temperature resistant high quality glass refining double reflux integration standard mouth condensate pipe sleeve standard grinding mouth collection |

|

Rotate speed |

Electronic stepless speed regulation |

20-200 rmp |

Power 40 w |

||

|

Heating bank |

Teflon composite pan |

Fully enclosed heater |

Power 1.4KW |

||

|

Temp range |

Automatic temperature control |

Digital water temperature |

Room temp.-90℃ |

Feeder |

The valve type feeding pipe is nested with teflon pipe |

|

The total power |

1.5KW |

Voltage |

220/50Hz |

Sealer |

Fluororubber vacuum sealing gasket |

|

Feature |

The main components are made of rust-proof alloy and special engineering plastics, with compact structure, beautiful appearance and durability. |

||||

Structure