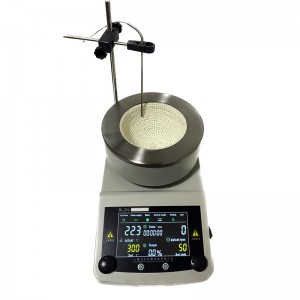

PTHW Thermostatic Heating Mantel

Introduction

PTHW electric heating jacket is an electric heating jacket that realizes constant temperature heating through electronic pressure regulation, it is made of alkali-free glass fiber as insulating material, Cr20Ni80 alloy wire spring device in it, with aluminum silicate cotton by vacuum shaped hemispherical insulation body insulation, shell one-time injection molding, the upper cover adopts electrostatic spraying process, because of the use of spherical heating, can make the container heated area of more than 60%, with fast temperature rise It has the characteristics of fast temperature rise, high temperature, easy operation and durability.

Operation method

Plug in the power supply, the green light indicates power supply, the red light indicates heating, adjust the knob in clockwise direction, the temperature will be from low to high, when the knob is adjusted to a certain scale, the set reaches a certain basic constant temperature, but the thermometer is needed to assist in measuring. The initial heating can be adjusted appropriately high or to the highest temperature, when rising to the required temperature or solution boiling, the knob can be adjusted down for insulation heating to extend the service life, a short period of time without use, the knob can be adjusted to 0, that is, to stop heating. When not in use for a long time, it is necessary to turn off the plug-in power supply.

Notes

1. The instrument should be well grounded.

2. When using for the first time, there is white smoke and odour coming out of the set, the colour changes from white to brown and then to white, which is a normal phenomenon, because the glass fibre contains oil and other compounds in the production process, it should be put in a ventilated place and can be used normally after a few minutes disappear.

3. 3000ml or more electric heating set when using the squeak - squeak sound is the furnace wire structure is different and with the silicon regulator pulse signal, can be used with confidence.

4. When the liquid overflows into the set, please turn off the power quickly, put the electric heating set in a ventilated place and wait for it to dry before using, so as to avoid the danger of leakage or electrical short circuit.

5. When not in use for a long time, please keep the heating set in a dry place without corrosive gas.

6. Please do not heat the set empty or dry burn.

7. When the humidity is relatively high, induction electricity may be transmitted through the insulation layer to the shell, so please make sure that the earth wire is grounded to avoid electricity leakage and pay attention to ventilation.

The contents of this manual are subject to change without notice due to improvements in the product or the products covered by this manual.

Parameters

| Power supply | 220V 50Hz(110v50/60Hz also can be customised) | |||||||||||

| Temperature control model | Pressure regulation control | |||||||||||

| Accuracy control | ±2℃ | |||||||||||

| Temperature Heating | Surface temperature up to 380℃ | |||||||||||

| Furnace wire | Cr20Ni80 | |||||||||||

| insulation layer | Non-alkali glass fibre, temperature resistant to 450℃ | |||||||||||

| Insulation factor | ≥500 megs at ≤35% relative humidity | |||||||||||

| Insulation layer | Vacuum shaped eco-friendly insulated cups made from aluminium silicate cotton fabric | |||||||||||

| Volume(ml) | 50 | 100 | 150 | 250 | 500 | 1000 | 2000 | 3000 | 5000 | 10000 | 20000 | 50000 |

| Power(w) | 110 | 130 | 170 | 210 | 230 | 530 | 650 | 730 | 1100 | 2100 | 3000 | 5000 |

| top opening diameter(mm) | 58 | 75 | 80 | 95 | 115 | 145 | 180 | 212 | 253 | 305 | 384 | 465 |

| set depth | 35 | 40 | 40 | 60 | 70 | 85 | 105 | 125 | 145 | 175 | 205 | 300 |

| casing diameter | 200 | 200 | 200 | 230 | 230 | 260 | 270 | 300 | 340 | 400 | 480 | 635*635 |

| Casing height | 140 | 140 | 140 | 155 | 155 | 165 | 190 | 200 | 230 | 260 | 300 | 550 |

| Weight | 1100 | 1200 | 1200 | 1300 | 1300 | 1500 | 2930 | 3000 | 4550 | 6850 | 8350 | 28200 |