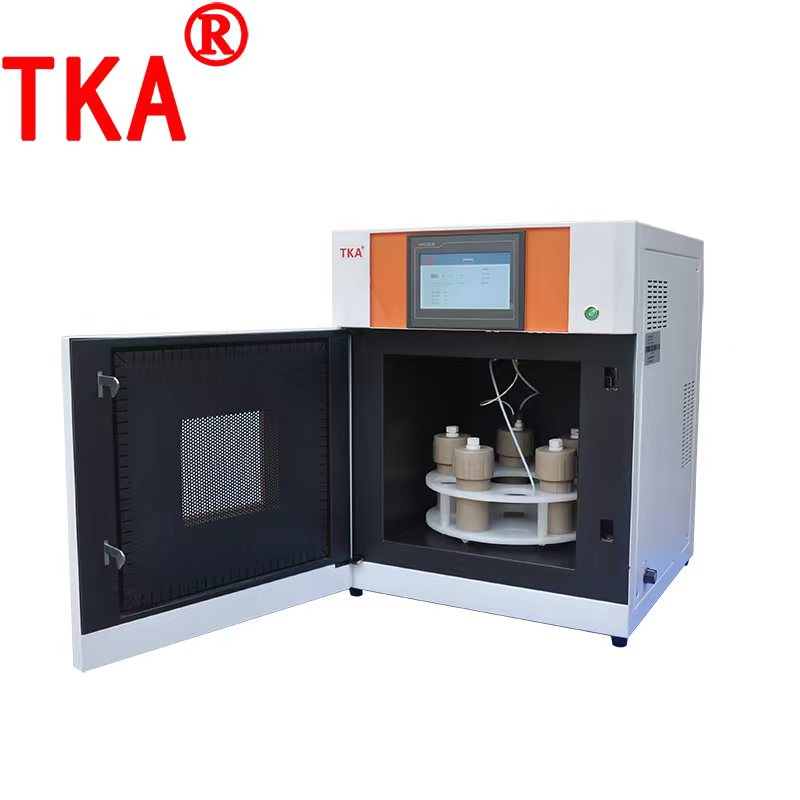

High-throughput Intelligent Microwave Dissolver.

Feature

It adopts microwave non-pulse continuous automatic frequency conversion control, which prolongs the service life of the instrument and the uniformity of electromagnetic wave, the cavity is made of 52L large volume 316L stainless steel cavity material, self-locking buffer explosion-proof furnace door, when the reaction is abnormal, the buffer structure ensures the safety of the operator and the structure of the furnace door is intact and undamaged, the combination of the furnace door and the cavity is tight, the leakage of microwave is in line with the national standards. The instrument adopts temperature and pressure dual-control system to control the pressure and temperature of the ablation experiment, with real-time display. 360°simultaneous continuous rotation, microwave uniformity, to ensure that the microwave environment of each sample is the same, to improve the consistency of the experimental results. When the pressure in the tank exceeds the set protection value, the microwave will automatically stop heating. The safety explosion-proof film has double insurance function, when the pressure inside the tank exceeds the pressure that the explosion-proof film can withstand, the explosion-proof film ruptures first, and the gas is discharged, which prevents the tank from being damaged and the human body from being harmed.

Parameters

| Model | TKWB-6 | TKWB-10 | TKWB-12 | TKWB-16 |

| Mainframe | Power supply: 220-240 VAC 50/60Hz 8A; Microwave frequency: Microwave source/2450MHz; | |||

| Microwave output power: 0~1600W automatically and continuously adjustable; Microwave output characteristics: microwave non-pulse continuous automatic frequency conversion control, 0 ~ 100% automatic output; |

||||

| Microwave cavity: 52L, 316L all stainless steel cavity, 6 layers of anticorrosive high temperature Teflo n coating; corrosion resistance, high temperature resistance; | ||||

| Exhaust and cooling system: The furnace chamber is equipped with a high-power exhaust system, so that all kinds of reactions can be carried out continuously for a long time in a ventilated, safe and easy-to-see environment. Furnace chamber ventilation adopts acid-etching resistant, large air volume centrifugal fan, the exhaust air volume is not less than 5m3/min; the furnace chamber has the function of air-cooling, which continuously cools down the reaction tank, and the temperature and pressure are displayed in real time. | ||||

| Control System | ;Control mode: touch screen design, 8-inch TFT-LED (800X480 colour) large screen display, direct reading of the reaction process from a distance, real-time display of the temperature and pressure of the closed reaction tank, and real-time display of the temperature and pressure curve; | |||

| Temperature control range: 0~300ºC; temperature control accuracy: ±0.5ºC; | ||||

| Temperature control system: adopting contact temperature control mode, precise and error-free temperature control, using platinum resistance temperature sensor; real-time detection, control and display of the temperature and curve in the microwave digestion reaction tank; | ||||

| Pressure control system: adopting non-contact pressure control mode, accurate and error-free pressure control, real-time detection and control and display of the pressure and curve in the microwave digestion reaction tank; pressure control range: 0~6MPa, 0~10MPa, 0~15MPa optional; pressure control accuracy: 0.01MPa; | ||||

| Pressure protection: overpressure automatically adjusts/stops microwave transmission and automatically alarms; | ||||

| Reaction Tank | Temperatures can reach over 300°C and pressures up to 1500 psi; | |||

| The outer tank is made of imported PEEK aerospace material, and the inner tank is made of polytetrafluoro material; the reaction volume of the inner tank is 100ml; | ||||

| High pressure digestion tank batch capacity 6 samples/batch; | High pressure digestion tank batch capacity 10 samples/batch; | High pressure digestion tank batch capacity 12 samples/batch; | High pressure digestion tank batch capacity 16 samples/batch; | |