-

Fixed-bed Catalyst Evaluation Units

Overview The fixed-bed catalyst evaluation device is equipped with two gas inlets and one liquid inlet, the gas inlet is precisely controlled by a gas mass flow controller, and the liquid inlet is controlled by a precision metering pump. The device adopts a reactor with three sizes of reactors, w... -

Synthesis Gas Separation Experiment Conversion Device

Process flow of the device The gas from the cylinder firstly enters into the buffer tank for preliminary gas-liquid separation, and at the same time regulates and stabilises the gas volume. The gas from the cylinder firstly enters the buffer tank for preliminary gas-liquid separation, and at the ... -

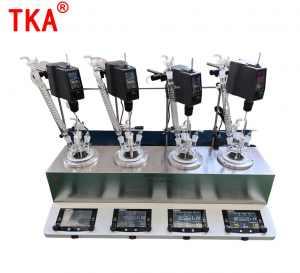

Parallel Synthesis Glass Reactor with Individual Temperature Control

It is used in single or parallel synthesis, Experimental design, Process development,scale up,Routing Search,Crystallisation studies, Polycrystalline Screening; Lead optimization,Reaction optimisation;Reagent, catalyst and solvent screening.

-

Electrochemical Autoclave Reactor

Mixing Reactor,Chemical High Pressure Reactor,Stirring Autoclave,Stainless Steel Autoclave,Reaction Kettle Reactor,mixer,reactor,stainless steel tank,chemical equipment,pressure vessel,high pressure reactor,Mixing Reactor,Hydrogenation Reactor,Lab Reactor,Chemical High Pressure Reactor ,Autoclave Reactor ,Stainless Steel Reactor

-

High Pressure Micro Autoclave Reactor Price with Stirring for Lab

It is suitable for the hydrothermal synthesis of single crystal reactions, CO2 reduction, CO2 reduction to methanol, CO2 reduction to CH4, and NOx degradation. Catalytic reactions include the Fischer-Tropsch reaction, hydrogenation reactions, polymerization reactions, homogeneous reactions, and CO2 supercritical reactions, among others.

-

Lab Vacuum Pump Degree Pressure Controller

Overview Vacuum degree controller is a high precision vacuum controller developed by our company. The instrument uses an imported anti-corrosion pressure sensor and a high-sensitivity solenoid valve for high-precision control of the vacuum. It can be equipped with rotary evaporator, rectification... -

100ml High Pressure Chemical Stirring Reactor Stainless Steel Reaction Kettle.

Product Description: Mechanical high-pressure reaction kettles are best suited for the reaction of mediums with high viscosity. The motor is mounted on top and operated by a magnetic coupling drive; the magnetic sealing is safe, and there is no leakage. Suitable for laboratory worktables, compact... -

Mechanically stirred Autoclave reactor with Teflon Liner

Product Description: Mechanical high-pressure reaction kettles are best suited for the reaction of mediums with high viscosity. The motor is mounted on top and operated by a magnetic coupling drive; the magnetic sealing is safe, and there is no leakage. Suitable for laboratory worktables, compact... -

TKA Top View Photocatalytic Reactor

Application examples: Top view photocatalytic reactor is suitable for photocatalytic high pressure reactor, carbon dioxide reduction of methanol, carbon dioxide reduction to make methane, reduction degradation of nitrogen oxides, high pressure photocatalytic degradation of formaldehyde and oth... -

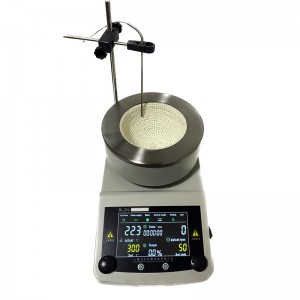

up to 400 º C Magnetic Stirring Heating Mantles

Power supply: AC220V±10%,50Hz~60Hz. Temperature control range: room temperature~400℃. Temperature control accuracy: ±0.1℃. Resolution of temperature measurement: ±0.1℃. Speed range: 50~2000rpm, digital display. Air speed precision: ±1r/min. Electrode power: 40w~60w, Dc-24V. Stirring capacity:... -

500ml,1000ml,2000ml Lab Electric Heating Mantle.

Power supply: AC220V±10%,50Hz~60Hz. Temperature control range: room temperature~400℃. Temperature control accuracy: ±0.1℃. Resolution of temperature measurement: ±0.1℃. Speed range: 50~2000rpm, digital display. Air speed precision: ±1r/min. Electrode power: 40w~60w, Dc-24V. Stirring capacity:... -

400℃ Lab Magnetic Stirrer with Digital Temperature Control.

Power supply: AC220V±10%,50Hz~60Hz. Temperature control range: room temperature~400℃. Temperature control accuracy: ±0.1℃. Resolution of temperature measurement: ±0.1℃. Speed range: 50~2000rpm, digital display. Air speed precision: ±1r/min. Electrode power: 40w~60w, Dc-24V. Stirring capacity:...