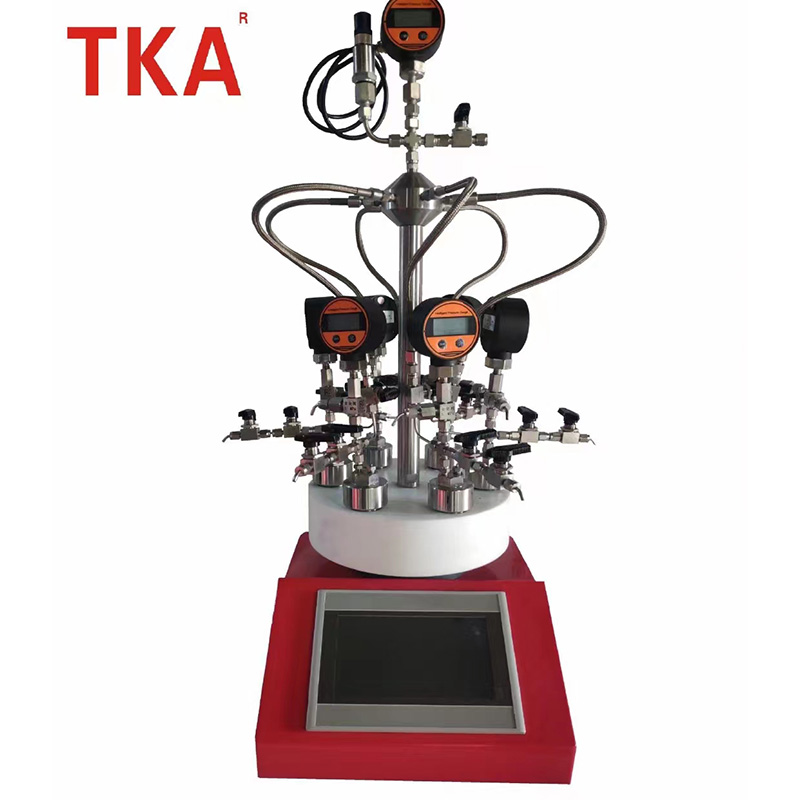

High Temperature High Pressure Stainless Steel Parallel Bio Reactor with 6 Work Stations.

Detail

Parallel high pressure reactor is referred to as high pressure vindication. It is a new type of reaction synthesis scientific research instrument that combines the basic principles of synthetic chemistry and the concept of combinatorial chemistry. The so-called high-pressure parallel synthesizers, parallel reactors, parallel synthesizers, organic synthesis devices, parallel catalytic screening and evaluation and other reaction devices are all other names of such instruments. It is one of the necessary equipment for the exploration of reaction routes, optimization of conditions and efficient synthesis in the research and development of modern synthetic chemistry. Parallel reaction is suitable for modern reaction synthesis equipment with strict requirements on anhydrous, oxygen-free and air tightness of the system, wide temperature control range, accurate temperature control accuracy, strict reaction safety requirements, high scientific research efficiency requirements, and good repeatability requirements.

Products Parameter

|

Model |

GPXF-6-50ml |

Type |

Independent Parallel reacor |

|

Main engine |

RCT Imported from Germany |

Reactor |

6 pieces *50ml, material :316L stainless steel, pressure resistant; 10Mpa, temperature resistance: 250℃. Practicability: can be used together and independently |

|

Sensor |

PT1000 imported from Germany |

Model |

Six hole heating module |

|

High temperature |

300℃ |

Needle valve |

14pieces (7 intake valves, 6 one-way valves), 1 safety valve |

|

Connector |

There are 6 four-way pieces, 1 three-way piece and 6 shunting pipelines |

Pressure Gauge |

A total of 7, 1 main table, 6 sub-tables |

|

Temperature measuring points |

7, one for the main engine, and one for each of the six cauldrons |

Sampler |

6 pieces online samplers, material 316L stainless steel |

|

Heating power |

800(w) |

Reaction volume |

6piecces* 50(ml) |

|

Stirring speed |

1500 (RPM) |

PTFE inning |

PTFE inner 6pieces, volume 50ml |

|

Inflation hose |

Withstand pressure 20Mpa, 1.8 meters long |

Gas diverter |

Six-way split, 316L stainless steel |

|

Precision pressure gauge |

Pressure and shock proof pressure gauge, maximum range of 10Mpa |

Application range |

Exploration of experimental conditions such as multi-site crystallization reaction, multi-site hydrogenation reaction, parallel reaction without water and oxygen. |

Functional Introdaucion

1. The 6 work stations reactor can carry out synthesis reaction, inert gas condition reaction, etc. under the same or different conditions.

2. The reaction temperature conditions are from room temperature to +300 ℃ LED digital display, the keys can be set arbitrarily, and the control accuracy is 1 ℃.

3. Rotational vibration function of the reaction platform: 0-1500 r/min rotary vibration LED digital display, button to adjust the speed at will.

4. It can work independently or in series at the same time, and the design of independent sealed kettle cover will not produce cross-contamination.

5. Temperature control mode: high temperature adopts PID control heating constant temperature digital display, temperature control accuracy ± 1 ℃.

6. The module capacity is six holes, and the maximum temperature difference of the same module is ±0.2℃, which can effectively ensure the accuracy of the experimental data.

7. Power supply voltage 220V/50HZ machine power 800W