Edible Oil Processor Cold Oil Press Machine Small Scale Oil Extractor Oil Refinery Plan

Feature

1.Fast and efficient

The complete extraction of the materials in the container can be completed within one minute, and the degree of crushing is appropriate, which is conducive to the full extraction of effective ingredients and filtration.

2.Normal temperatureextraction

The instrument works in a suitable solvent at room temperature to avoid the damage of effective components due to heating.

It is suitable for rapid extraction of roots (decoction pieces), leaves, flowers, fruits and other parts of plants.

3.Widely applicable

a. it is suitable for a variety of solvents. In addition to flammable and volatile solvents such as ether, acetone (or aqueous acetone), methanol (or aqueous methanol), ethanol (or aqueous ethanol), cold and hot water can be directly selected as solvents for extraction according to the required effective parts or chemical components, which is a simpler process.

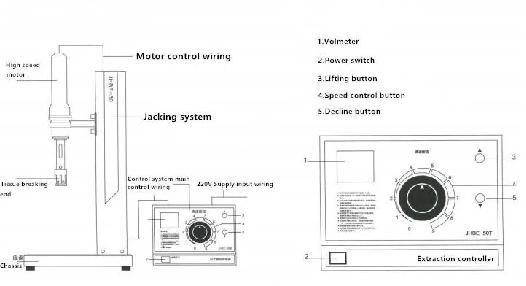

b.The design of the equipment is scientific, reasonable and easy to operate. The structure is firm and reliable. The electrical part does not contact solvents and does not contain electric leakage. The speed of the blade depends on the manual control of the governor. It can be adjusted or stopped at any time as needed. The blade rotates in a fixed external shaft gun, which is very safe.

Parameter

| Model |

JHBE-50T |

|||

|

Working Condition |

Environment temperature |

≤40degrees |

||

|

Motor temperature |

≤80degrees |

|||

|

Supply power |

220VAC=/-10%50Hz |

|||

|

Main components |

Operating box |

Display mode |

Instrument display |

|

|

Speed control |

0-15000/min |

|||

|

Lifting control |

Button control |

|||

|

Input |

220VAC |

|||

|

Output |

Six core integrated control |

|||

|

Main engine |

High speed motor |

Voltage |

220VAC |

|

|

Current |

8A |

|||

|

Power |

1800W |

|||

|

Revolving speed |

10000r/Min |

|||

|

Frequency |

50Hz |

|||

|

Lifting motor |

Voltage |

220VAC |

||

|

Current |

0.29A |

|||

|

Power |

10W |

|||

|

Revolving speed |

120r/Min |

|||

|

Frequency |

50Hz-60Hz |

|||

|

Lifting induction |

Model |

7411 |

||

|

Voltage |

220VAC |

|||

Troubleshooting Method

|

ROLAccident |

Cause |

Solution |

|

No Electricity |

The power supply without power |

Checking power cables |

| Electric leakage protection | Protector reset | |

| not plugged in properly | to confirmed the plug in place | |

| Fuse is blown | Replacement of fuse | |

|

Motor no Working |

Buzzing but not turning | Remove the tool bit and take out the material inside |

| Speed control button does not respond | Check the integrated control line and motor switch | |

|

Tool bit does not rotate |

Tool bit loose | Check whether the nut is loose |

| Bearing damage | Replacement bearing | |

| Tooling bit stuck | Manually clean the material above the tool bit | |

|

Lift button failure |

Button damage | Replacement button |

| Capacitor burn out | Repalce a capacitor of the same model | |

| Lifting motor damage | Replacement of lifting motor | |

|

Voltmeter does not display |

Voltmeter damage | Replace the voltmeter |

|

Fuse is blown |

Fuse during startup | Check that the tool bit is functioning property |

| Short circuit | Check each wiring system | |

| Fender size too small | Replace high current fuse |

Main Engine Struture Drawing