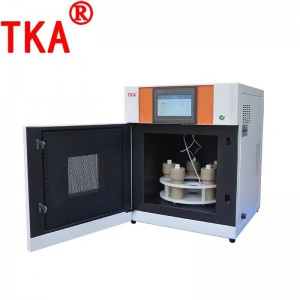

China Mini Microwave Chemical Reactor Supplier

Products Introduction

In recent years,the development of microwave chemistry technology be just unfolding,the scientific community has been on the microwave energy in the extraction and synthesis.Filed application has paid a great deal of attention.Due to thermal effects of microwave,the non thermal effect,induced catalytic effect should special mechanism for chemistry,especially in organic synthesis field has brought great impact Hammer.Application of microwave in organic synthesis reaction,the reaction speed to accelerate from ten to thousands of times than that of conventional methods.And Synthesis of conventional methods are diffcult to synthetic substances.So far,research and achieved effect have Diels-Alder cycloaddition reaction,rearrangement reaction, esterification reaction,Pekin reaction,alkylation,oxidation,substitution,condensation,addition and polymeriation.Are widely used in pharmaceutical,chemical and related materials,teaching and Acientific research field,As a professional production of laboratory equipment manufacturers,we according to the requirements of customers,push the MCR-3 type microwave chemical reactor suitable for normal pressure synthesis and extraction reaction.

Technical Featureas and Description

Non pulsed microwave continuous heating:Studies show that pulse microwave can produce can produce high threshold electromagmetic pulse in the “on” and “off” the moment,the temperature overshoot or sharp shock phencomenon,but also easy to destroy the organic molecular shape,consistency and thus affect the experimental results,Non pulsed microwave continuous heating and its characteristics are:power frequency microwave adjusting,microwave output for the continuous output,no pulse stimulation.

Microwave power frequency control:Using double CPU technology,monitoring control.Adaptive PID control technology,changes in environmental temperature,reactand polarity,the change in the heat capacity,the mathematical model under varying conditions,has overcome the overshoot phenomenon,The microwave temperature feedback and adjust the microwave power,which can accurately reach the set temperature value,The severe degree of automatic power adjustment size and reaction,to achieve the ideal.

Platinum resistance temperature control systen:shielded platinum resistance is directly inserted into the reactor,temperature measuring reaction inside,according to accurate shielding device is reliable and eliminate and electromagnetic interference and self heating effect.

Microwave power is ten files regulation:We in the microwave power can be divided into ten files,the power range of microwave can be defined in each file automatic frequency control,so as to limit the severity of reaction,and the reaction speed,reaction temperature,reaction time,and the maximum power.Microwave at work can not stop change reaction conditions.

Five step heating procedure:Through the control of a microcomputer,we can male the reaction temperature rising process divided into five stages,a user can edit all reaction parameters.

Large liquid crystal display:The screen size is 120*80mm.Synchronous display real-time working period,the ower setpoint,The setting temperature,setting time,Real time power,real-time.Through the page,and can display temperature curve.

Equipped with inert gas inlet,the built-in magnetic stirrer.The stirring speed stepless adjustable.

The user can according to the reaction vessel reaction conditions of arbitrary with standard interface(50-500ml),and reflux condensation,Dripping,rehydration and water diversion device.

Specification

|

Model |

MRC-3 |

|

Furnace chamber volume |

28L |

|

Power supply |

AC 220±10% 50Hz |

|

Total input power |

≤1300W |

|

Microwave frequency |

2450MHz±50Hz |

|

Microwave output mode |

continuous wave |

|

Microwave output power |

≤750W(continuously adjustable automatically) |

|

Temperature |

Room temperature~250℃ |

|

Time |

Time can be set to 5*999 seconds |

|

Temperature measurement accuracy |

0.2 |

|

Temperature control accuracy |

≤1℃ |

|

Temperature measurement method |

contact PTFE temperature sensor |

|

Maximum use temperature |

≤250℃(optional setting) |

|

Operating procedures |

Each experiment can be set to 5 steps.each step individually set. |