Chemical 20L Double Layer Glass Reactor with Ce

Product Feature

1. Frequency-controlled, AC induction motor. Constant speed, no brushes, no sparks, safe and stable, can work continuously.

2. The complete set of glass instruments is made of GG17 high borosilicate glass, which has good chemical and physical properties.

3. The glass laminated interface is circulated with hot oil for heating reaction and with freezing liquid for low temperature reaction.

4. The reaction can be carried out at room temperature, and the heat can be quickly removed by passing tap water.

5. With flanged mouth and PTFE valve, there are no dead corners in the vessel and it can be dismantled to facilitate the discharge of solid materials.

6. Six-port reactor lid, extra large port design for easy cleaning, standard port socket for optional assembly of reflux, distillation synthesis device.

Products Parameter

| Model | TK-SF20L |

| Dimensions(mm) | 500*500*2200 |

| Outter package(mm) | 1200*550*700 |

| Total weight(KG) | 80 |

| Kettle volume(L) | 20 |

| Jacket volume(L) | ≈5 |

| Voltage/frequency(V/Hz) | 220/50 |

|

Glass withstanding temperature(℃) |

-120~300 |

|

Display temperature range(℃) |

-50~200 |

|

Up to vacuum level( MPA) |

-0.098 |

|

Mixing speed(rpm) |

0-600 |

|

Power(w) |

120 (1:3) |

|

Mixing shaft diameter(mm) |

12/14 |

|

Speed control method |

Frequency conversion |

|

Seal form |

PTFE |

|

Number of lid openings |

Six ports (optional) |

|

Glass material |

GG-17 High borosilicate glass |

|

Temperature measurement holes |

φ35 |

|

Drip hole |

#40 |

|

Mixing holes |

φ60 |

| Reflux hole | φ50 Ball port |

| Air vent/liquid feed hole | #34 |

| Feed hole | φ80 |

|

Condensation holes |

#40 |

|

Drop-in |

1000ml constant pressure funnel |

|

Temperature measurement |

Gauge Thermometer |

|

Exhaust/inlet |

#34 Glass valve |

|

Backflow |

500ml reflux elbow |

|

Feeding port |

PTFE |

|

Discharge |

Top-loading glass valves |

|

Stirring |

Four Paddle |

|

Condenser |

Vertical serpentine condensing coils |

|

Optional items |

Explosion-proof/pallets/sprayed Teflon/inverter controlled speed |

|

Other |

Customised modifications available on request |

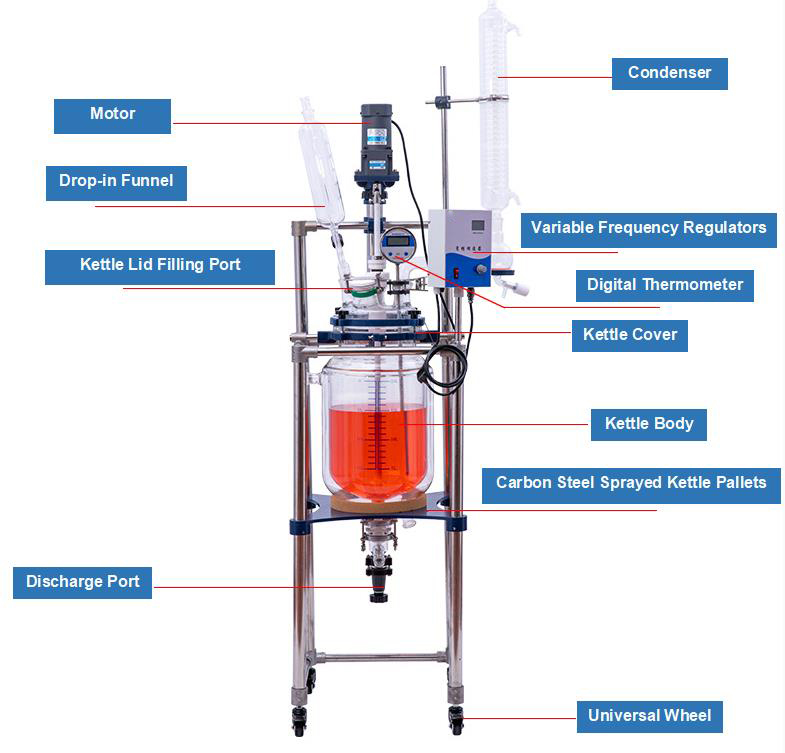

Structure