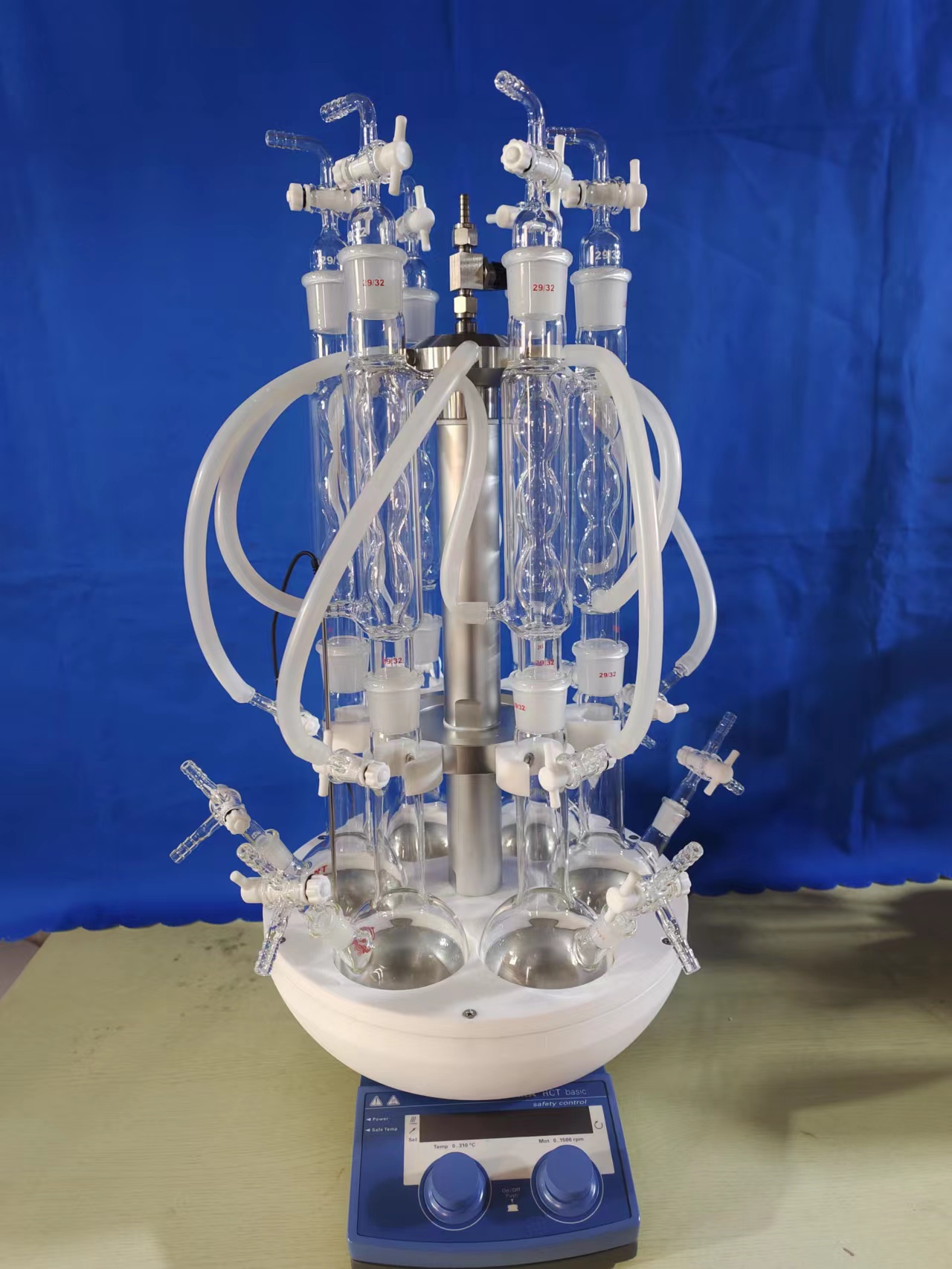

TK-PXF 6*250ml Tubular Glass Parallel Reactor

Working principle

Parallel synthesis reactors are a new class of research instrument that combines the basic principles of synthetic chemistry with the concept of combinatorial chemistry. Parallel synthesizers, parallel reactors, parallel synthesizers, organic synthesis devices and parallel reaction workstations are other names for this type of instrument. It is one of the necessary equipment for reaction route exploration, condition optimisation and efficient synthesis in modern synthetic chemistry research and development. The All-In-One Parallel Reactor has greatly enhanced the functionality and extended the range of applications of this type of instrument. The parallel reactor is suitable for modern reaction synthesis scientific research where the system is water and oxygen free and gas tight, the temperature control range is wide, the temperature control accuracy is accurate, the reaction safety is strict, the research efficiency is high and the reproducibility is good.

Basic Configuration:

• 10pieces reaction sample tubes can be used under the same or different conditions for synthetic reaction, reflux extraction reaction, inert gas condition reaction, in situ distillation and concentration reaction, anhydrous and oxygen-free experiments and parallel low-temperature reaction of multiple tubes and other functions.

• The reaction temperature conditions are set arbitrarily from -20℃ to +200℃, and the control precision is 1℃.

• Reaction platform cyclic vibration function: equipped with IKA imported magnetic stirrer, 0-1500 rpm cyclic vibration, touch button to adjust the speed and temperature.

• independent sealing bottle cap design, will not produce cross-contamination, in the sealed state can be added to the test tube reaction reagents. Ten condensers are directly inserted into the reactor with good cooling effect and interchangeable.

• Temperature control mode: high temperature using PID control heating digital display, temperature control accuracy ± 1 ℃. The low temperature adopts circulating pipeline refrigeration cooling mode, temperature control accuracy ± 3 ℃.

• Ten holes of the entire heating module to ensure that the same module maximum temperature difference of 0.5 ℃.

• Power supply voltage 220V/50HZ, 110V optional. Machine power 600W.

Technical Parameters

|

Model |

PXF-6*250ml |

Type |

Parallel synthesis reactor |

|

Mainframe |

RCT imported from Germany |

Reactor |

6pieces quartz glass tubes |

|

Condenser |

6 pieces Sphere Return Condensing tube, JGS2 quartz glass. |

Modules |

6-hole heating and cooling module |

|

Sensors |

PT1000 Imported from Germany |

Gas dispersion splitters |

One F4 tetrafluoroethylene 6-way gas splitter and 6 gas replacement valves. |

|

Valves |

18 pieces Teflon valves |

Volume |

250ml*6pcs |

|

F4 tray |

Polytetrafluoroethylene 6 hole stabilised tray |

Power |

600(w) |

|

High Temperature |

250℃ |

Low temperature |

-20℃ |

|

Stirring speed |

50-1500rpm |

Heating Modules |

400mm |

|

Overall Dimension |

680H*450W*450D(mm) |

Stirrer bar |

6Pieces |

|

Scope of application |

Anhydrous and Oxygen-free Omnipotent Parallel Reaction is one of the necessary equipments for the exploration of reaction routes, optimisation of conditions and efficient synthesis in modern synthetic chemistry research. |

||