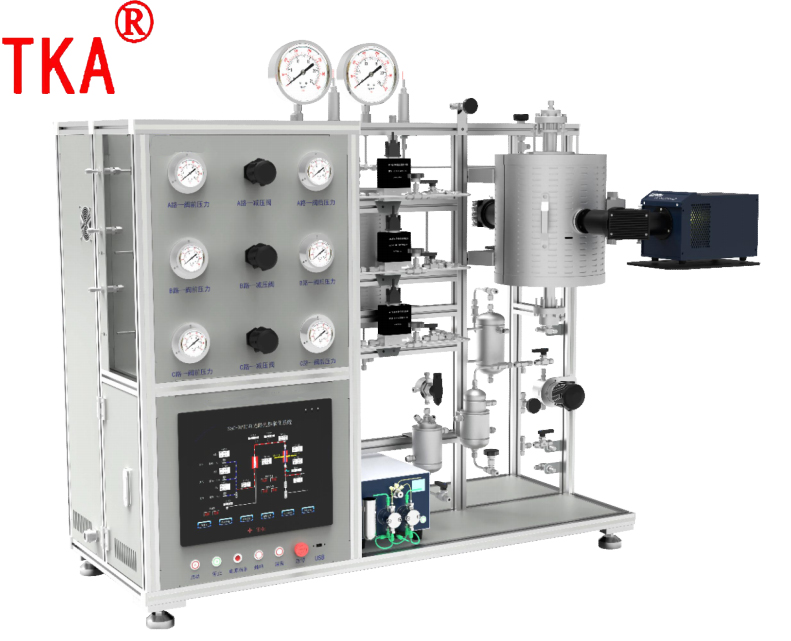

Dual Light Path Photothermal Catalysis System

System Advantages

1.Pressure-reducing system in the system, which can be directly connected with the reaction gas cylinder, the pipeline is equipped with proportional unloading valves, high-precision pressure gauges and pressure sensors, and all temperature control points and pressure monitoring points are equipped with over-temperature and over-pressure alarms for automatic interlocking protection.

2.Feeding system, when passing into different gases, the corresponding gas flow coefficient can be selected or inputted in the flow coefficient table, so as to realise the diversity and accuracy of gas types.

3.Mezzanine temperature-controlled standard gas module, reaction liquid such as toluene, ethanol, etc. in the pressure-resistant tube, pass into the reaction gas or inert gas into the module, bring the effective gas of ppm level into the reactor, control the temperature of the module and then control the concentration of the gas through the water-bath circulating water machine; thus, it can greatly reduce the cost of the experiment and solve the difficult problem that the standard gas is expensive.

4. Constant pressure system, with low pressure and high pressure dual pressure system, according to the experimental pressure to select the corresponding pressure system, to provide stable and accurate, stable experimental environment for the catalyst.

5.The system control all adopts PLC software automation control, real-time monitoring of the reaction process, automated data processing, and provide a full set of experimental programmes. The screen adopts industrial control touch screen PLC, which can be used to change the programme at any time according to the demand. Xinshi Ke shinsco provides gas chromatograph, liquid chromatograph, electrochemical workstation, TPR, TPD, SPV, TPV, Raman and other testing and analysis instruments.

6) The system integrates feeding system, constant pressure system, steady flow system, preheating system, reaction system, product collection system and PLC control system.

Main technical parameters:

1.Pressure: photothermal catalysis pressure <5MPa (design pressure 8Mpa), conventional thermal catalysis pressure <5MPa (design pressure 10MPa).

2.Temperature: <800ºC; constant temperature of working area: length 30mm, <±1ºC; heating furnace: 2 sections;

3.Reactor working area light: diameter 30mm, double-sided irradiation, using quartz reaction tube, quartz light guide tube;

4.Quartz reaction tube, effective working area 30mm, diameter 10mm, built-in temperature measurement probe, light area <10cm2, catalyst loading <1ml, pressure resistance <5MPa;

5. Placement of filter and converging lens at the position of light inlet to achieve the selection of spectrum and adjustment of light intensity;

6.Pre-heating furnace parameters <5MPa, <600ºC, to improve the mixing effect and warm the reaction gas in advance to ensure the reaction temperature during catalysis;

7.gas-liquid mixing module, often used temperature range: -10 ºC ~ 95 ° C; design pressure: 5MPa; material: stainless steel 316L; with water bath jacket; the top of the air inlet, outlet, temperature measurement port and liquid port, the bottom of the liquid discharge port;

8.condenser: design pressure: 6MPa; material: stainless steel 316L; 300ml; coil condenser, leaving two water nozzles for connecting condensate.

9.Gas-liquid separator ![]() esign pressure:6MPa;Material:Stainless steel 316L;150ml;internal de-bubbling plate, the gas is discharged from the top and the liquid is deposited at the bottom.

esign pressure:6MPa;Material:Stainless steel 316L;150ml;internal de-bubbling plate, the gas is discharged from the top and the liquid is deposited at the bottom.

10. Control requirements: must use Mitsubishi or Siemens PLC control system, data acquisition and feedback control timely and reliable: temperature control accuracy: ± 1 ºC; pressure control accuracy: ± 0.1Mpa; gas flow control accuracy: ± 1%; liquid flow control accuracy: ± 1%.

11. three-way gas: you can choose any gas (containing dozens of gas options), N2 flow rate: 50, 100, 100ml/min

12. all the way liquid: containing spare liquid pipeline and liquid heating, liquid flow <5ml/min, <200 ºC, metering pump options;

13.Gas chromatograph GC: double FID + TCD three detectors + nickel-metal hydride conversion furnace programme, you can test all components, the use of pneumatic autosampling valve 10-pass + 6-pass (temperature control <200 ° C) to achieve the simultaneous analysis of the three detectors test online, to achieve the full-component analysis, anti-control automatic workstations.